| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : Filter

Model Number : FLT-FB-413

Place of Origin : Anhui

MOQ : 50pcs

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union

Supply Ability : Supply 10000pcs filter bags per month

Delivery Time : 3~15 days

Packaging Details : Carton or Woven Bag

product name : Nomex(Aramid) filter bag

Applicable Industrie : Cement Plant,Power Plant,Steel Plant,Mining Plant etc.

usage : Dust filter

Certificate : ISO9001:2008

Weight : 450GSM~550GSM

Size : Round/Flat/Custiomized

Material of bag : Aramid,PPS,PTFE,Polyester,fiberglass

surface finishing : Singed,Calandered,Heat-set,oil&watere repellent treatment

Top : SS304 sanpband or according to your requirements

Bottom : reforcement 75~100mm

Normal Temperature : 204deg.c

High temperature : 240deg.c

Shape : Round,Customers' Request

Package : OEM Package,polybags/cartons/customized

Micron rating : 99.99%

Name : Aramid/NOMEX dust filter bag

Oem : Welcomed

Keyword : aramid filter bag,nomex filter bag for steel plant

Produce 500GSM Aramid Nomex Filter Sleeves with SS Ring and High Temperature Glue:

Description:

We select Nomex Filter Fiber to produce the Nomex high temperature needle felt , it is the best filter material for high temperature fume / dust / ash, for steel plant, asphalt mixing, other metal industries .

The characteristics of nomex filter needle felt: High temperature (204~ 240 degree), anti -acid, anti-alkali, high filtration precision, blow speed, low pressure drop, anti -break, anti -abrasion, mostly applied in pitch mix gas, blast furnace gas in steel factory, tail gas of white char, kiln applications, electric cooker high temperature gas.

The normal specification of Nomex Filtration Felt :450 gsm , 500 gsm , 550 gsm , 600 gsm.

Threatment : PTFE coating, PTFE membrane, Water and oil repellemnt treatment .

Although we can tailor produce the size of Nomex Filter Bag for different Model of dust collector.

Technical Data:

| Fibre | Aramid |

| Scrim | Aramid |

| Weight(G/M2) | 450~550 |

| Thickness (mm) | 1.9~2.2 |

| Width (mm) | ≤ 2.2 |

| Length | 50m/roll |

| Finish treatment | Singeing, Calendering, Heat-set |

| Air permeability (L/m2/s): | 120~200 |

| Tensile strength (N/5× 20cm) | Warp:>800 Weft:>1000 |

| Tensile elongation (%): | Warp:<35 Weft:<60 |

| Temperature (ºC): | Continue: 204 Instant: 240 |

| Anti-acid | Excellent |

| Anti-alkali | Excellent |

| Anti-abrasion | Excellent |

Production Feature:

1. High efficient filtration level.

2. Depth type filtration.

3. Wide range of chemically compatible media.

4. High temperature resistance.

5. High flow efficiency.

6. High air to cloth ratio.

7. Various coatings are available.

Application:

1. Food and Beverage Industry.

2. Pharmaceutical Industry.

3. Non-ferrous Metallurgy.

4. Chemcial Plant.

5. Building Section and Mining Industry.

6. Cement Plant.

7. Power Plant.

8. Steel Plant.

Producing Process:

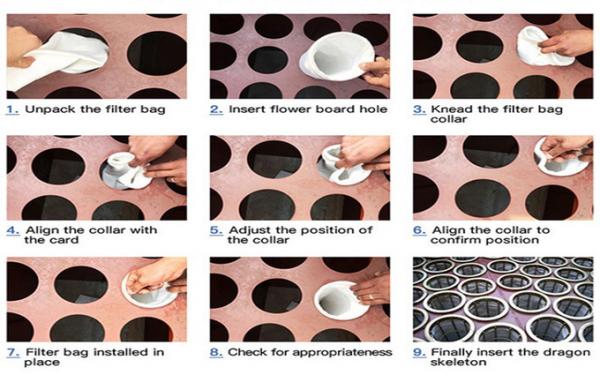

Install Diagram:

Applications:

More Production:

Packaging & Delivery:

Foreign Trade Team:

Exhibization:

Customer Visit:

Certificate:

Shipping Details:

| SHIPPING (Normally arrive port time in working days) | ||||

| Destination | Express/Courier | SHIP BY SEA | SHIP BY AIR | SHIP BY EMS |

| DHL/FEDEX/UPS/TNT | ||||

| North America | 3~7 days | 15~24 days | 5~7 days | 10~12 days |

| South America | 3~7 days | 15~25 days | 5~7 days | 10~12 days |

| European Countries | 3~7 days | 20~30 days | 5~7 days | 10~12 days |

| Africa Countries | 3~7 days | 40~50 days | 5~7 days | 10~12 days |

| The Middle East | 3~7 days | 15~25 days | 5~7 days | 10~12 days |

| Australia | 3~7 days | 10~15 days | 5~7 days | 10~12 days |

|

|

500GSM Aramid Nomex Filter Sleeves With SS Ring And High Temperature Glue Images |